Home » ISO Articles » 5 stages of Continual Improvement in ISO 9001 Quality Management System

5 stages of Continual Improvement in ISO 9001 Quality Management System

Overview

When organisations first implement their ISO 9001 quality management systems, there are often concerns. Because they are new to the management system processes and are going through the audit process for the first time, they worry that they are somehow not good enough, or that they won’t pass an audit because not everything is perfect.

However, this ignores a fundamental principle of operating an ISO 9001 quality management system: continual improvement.

Continual improvement can be achieved in several ways using ISO 9001. These are:

- the general routines that can be undertaken (e.g. auditing, checking and monitoring);

- Improvements to people through training; and

- Improvements to leadership – through good use of risk management and objective setting.

Fundamentally, improvement itself is a process, and it is unlikely that an organisation will go from a standing start to absolute perfection in one go. Think of success in sport – you need more than just one training session to become an Olympic athlete!

Making improvements to your quality management using ISO 9001 allows you to take 1 step at a time, which is the key thing to demonstrate to your customers and to your audit body. This article discusses that sequential approach to continual improvement using ISO 9001. Using the guidance in the ISO 9004 standard, the improvement model sets out a framework that you can easily apply within your business.

A Model for Quality Management System Improvement

To first approach Quality Management improvement, it is important to identify your goals and understand where you are in comparison to those goals. ISO 9004 sets out a useful model that will help you understand this.

If we focus this section on the operational processes that exist in most businesses, we can better explain how this works.

Consider your operational processes:

- Marketing and Sales

- Design and Development

- Purchasing

- Manufacturing or Service Provision

- Despatch, Delivery or Installation

- Warranties

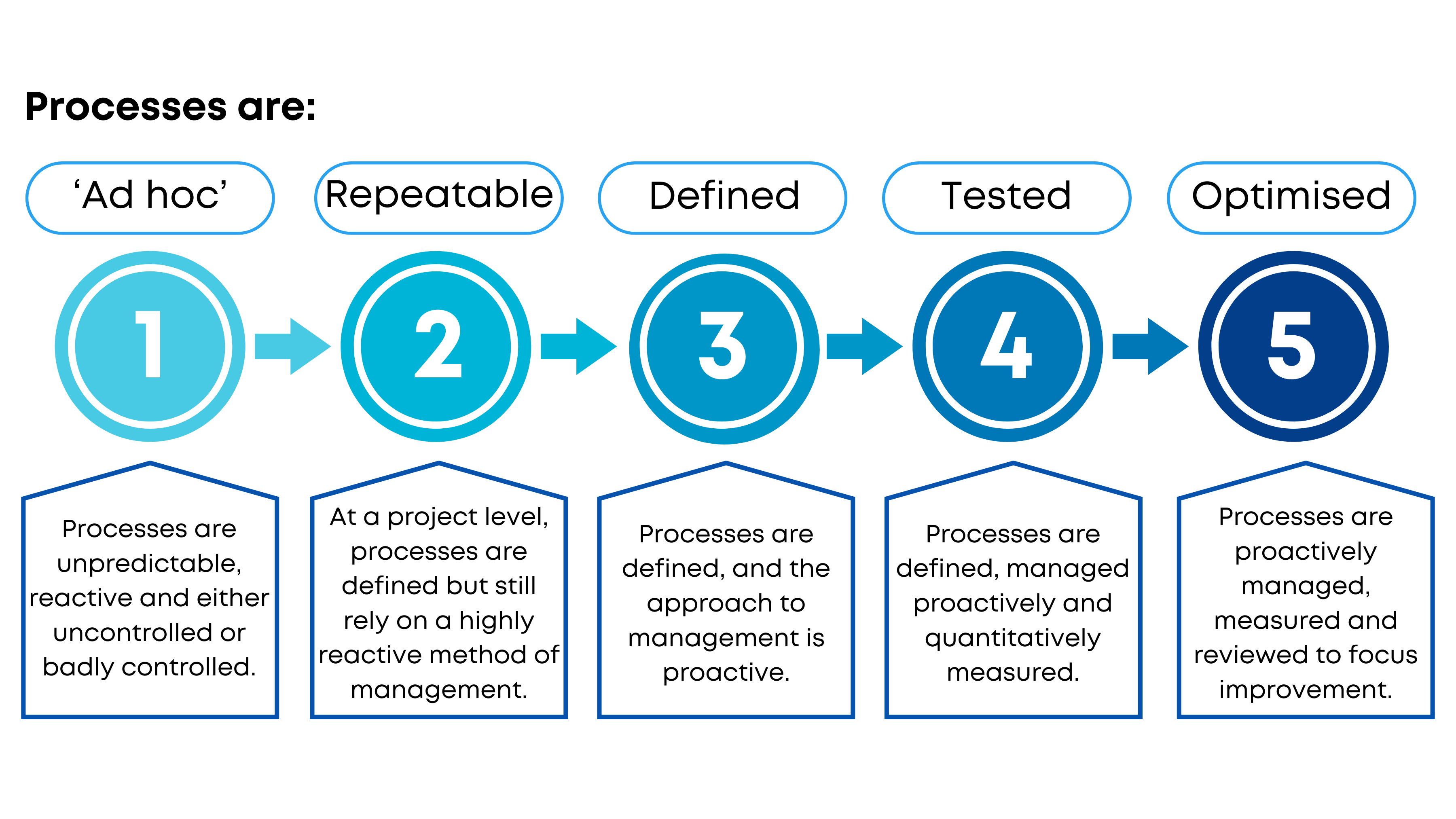

Using the levels described in the table below – consider:

- At what stage are your current processes?

- How good do you want these processes to be?

How To Use This Model for Quality Improvement

If you have answered the questions above about the level your business is currently operating at, you have formed a baseline.

If any of your processes are at level 1 and 2, you may be at risk of having non-conformances identified by your customers or your certification body. For ISO 9001, you should be aiming for at least level 3.

The next step is to identify the level you would like to achieve. Once you have done that, you can set an objective that sets out the time, responsibilities and methods of how you will achieve that goal. Further details are set out in ISO 9004, which will help with setting and defining goals.

The progression of your process improvement will always work through the levels:

- Moving from level 1 to 2; If you have processes that work in an ‘ad-hoc’ way, the first thing to do is document them, and train people to follow them, which will make them repeatable.

- Moving from level 2 to 3; If you have processes that are ‘repeatable’ at level 2, the next step is to define them fully; ensure that all process notes and variation are identified, that responsibilities are identified, and that these have been fully trained out to people.

- Moving up from level 3; this is where the improvement processes in clauses 9 and 10 will start to impact your operations – are you carrying out monitoring and analysis on the processes? Have you carried out audits? Have you engaged with your teams?

These activities will, over time ensure that the processes are tested and in turn optimised. A good indicator of whether a process is optimised is when the team that are using the process, discuss it openly and start to make improvements themselves. So, the team is consulting with the management team, rather than the other way around!

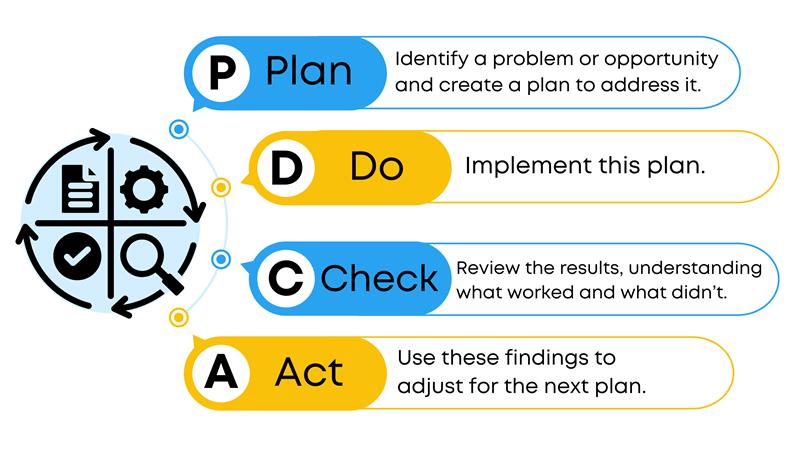

Once you have improved the processes that you have prioritised, you can apply your enhanced abilities of using the Plan-Do-Check-Act principle to other processes in your ISO 9001 Quality Management System.